- Cabinets

- Safety Storage Cabinets

- Flammable Storage

- Hand Sanitizer Storage

- Stainless Steel Storage

- Drum Storage

- Paint & Ink Storage

- Laboratory Storage

- Acid & Corrosive Storage

- Hazardous Waste Storage

- Wall Mountable Storage

- Pesticide Storage

- Weatherproof Storage

- Dual Access Storage

- Tooling Storage

- Cylinder Storage

- Medical Gas Cylinder Storage

- LP Cylinder Storage

- Single Wall Storage

- Industrial Storage

- Stainless Steel Storage

- Spill Containment Storage

- Custom Storage

- Custom Cabinets

- Custom Cabinet - Form

- Miscellaneous

- Drum Spill Stations

- Parts & Accessories

- Replacement Parts

- Features & Compliance

- Standard Features

- Code & Compliance

- OSHA Training

- Buildings

- Storage Buildings

- Hazmat Storage Buildings

- Chemical Storage Buildings

- Custom Buildings

- Custom Building - Form

- Tornado Shelters

- Tornado Safe Rooms & Shelters

- Bid Specifications

- Hazmat Storage

- Chemical Storage

- Frequently Asked Questions

- Steel Doors

- New Arrivals

- Distributors

- Contact Us

- Safety Storage Cabinets

- Cylinder Storage

- Single Wall Storage Cabinets

- Custom Storage Cabinets

- Drum Spill Stations

- Mobile Work Benches

- Safety Storage Buildings

- Tornado Shelters

- Distributors

- Code & Compliance

- Catalog

- FAQ

- Contact Us

- Home

FAQ - CABINETS

We have tried to include answers to the most asked questions about Securall Cabinets & Buildings. If we didn't answer your question below, please email it to us at custserv@Securallproducts.com.

WHERE CAN I FIND INFORMATION REGULATING THE PROPER STORAGE CAPACITY FOR MY NEEDS?

Securall Safety Storage Cabinets are designed to meet safety requirements whenever a job involves the handling of flammable or combustible liquids. For additional information regulating the proper application of storing flammables, please visit www.osha.gov or www.nfpa.org.

WHAT FEATURES COME STANDARD ON A Securall cabinet?

All Securall cabinets share the following features:

- Heavy-duty, reinforced 18-gauge all-welded construction

- Double wall construction with 1 ½” air space

- Galvanized steel shelving (except acid/corrosive and stainless steel cabinets)

- 3-point self-latching doors with all non-spark latching

- Flush mounted locking handle

- Continuous piano hinge

- Adjustable zinc plated leveling legs

- Two 2” vents with flash arrestors

- Large warning label

- Static grounding bolt complies with 2006 OSHA Regulations

- Leak proof sill 2” deep

- Finished in 2-part, chemical resistant and impact resistant urethane paint

WHAT ADDITIONAL OPTIONS ARE AVAILABLE FOR A SAFETY CABINET?

Securall offers a wide variety of cabinet options and accessories, including but not limited to additional shelves, venting and bonding kits, caster assembly, retrofit self-closing kit to convert any standard door cabinet into a safe-t-door unit, wall mount brackets (weight limit), stacking brackets (not recommended to stack self-closing cabinets beyond 200lbs). Other available options include: poly shelf liners and trays, sump liners, roller-bottoms, the outdoor weatherproof package (must be applied during manufacture of cabinet) etc. Installation of Non-OEM parts on the cabinet that alter the structural integrity of the unit will void the warranty and the FM approval.

WHAT IS THE DIFFERENCE BETWEEN A STANDARD DOOR, A SLIDING DOOR, AND A SAFE-T-DOOR?

All Securall cabinets are Self-Latching. All Securall cabinets utilize an OSHA & FM compliant non-sparking, 3-point spring loaded button latch system that automatically latches when the doors are closed.

The Standard Door model has a full piano hinge that will latch when door(s) are shut.

The Sliding Door model has a spring-loaded hydraulic controlled closer to employ OSHA 8 second Pinch-Point Regulation. Each sliding door cabinet comes with a fusible link to hold the door open during cabinet use. Fusible link will melt at 165° for automatic closure in case of fire.

The Safe-T-Door closure has not only a hydraulic cylinder to automatically close the door(s), but a built in pivot plate and safety mechanism allowing for an 8 second delay once the cylinder is engaged. Known as the OSHA Pinch-Point Regulation, this delay allows for removal of employee engagement from the doors before they close.

HOW CAN I TELL IF A CABINET HAS A PARTICULAR TYPE OF DOOR?

Securall denotes the door style in the hundreds place of the model number. Cabinet Models 100 are Standard or Manual door. Cabinet models 200 are Sliding Door, and cabinet models 300 are Safe-T-Door.

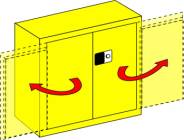

MY SELF-CLOSING DOOR CABINET IS NOT CLOSING ALL THE WAY. HOW CAN I ADJUST IT?

The most common reason that the doors won’t completely close is because the cabinet isn’t leveled. The cabinet is “level” for closing purposes when the tops of both doors are directly aligned with each other, signifying that the self-latching rod system inside each door is aligned with the body of the cabinet. Use the leveling legs that are located on the bottom 4 corners of the cabinet, and adjust them until the doors are aligned (as on a household appliance). If there are further questions, please contact your Customer Service Representative.

I NOTICED THAT THERE ARE PLUGGED VENTS ON MY CABINET. WHAT IS THE PROPER MEANS OF VENTING THE CABINET?

The National Fire Protection Association Code 30 (NFPA 30) Section 6.3.4 does not require safety cabinets to be vented. Check with your Local Authority having Jurisdiction, and if they do require venting, refer to the NFPA guidelines for proper application. Unless the cabinet is connected to mechanical ventilation system, the vent plugs must remain installed.

Most Schools and Universities will require a cabinet be vented.

WHAT IS THE STORAGE WEIGHT CAPACITY PER SHELF?

Securall has a uniquely designed shelf strip that will allow for 500 lbs per shelf (226.8 kg).

WHAT CODES DO Securall cabinetS ADHERE TO?

Factory Mutual (FM), National Fire Protection Association Regulations (NFPA), Life & Safety Code

Environmental Protection Agency Regulations (EPA), and Uniform Fire Code (UFC).

WHAT COLORS ARE AVAILABLE FOR MY CABINET? DO I HAVE TO USE A STANDARD COLOR?

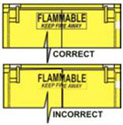

Although specific colors are common to certain stored materials (ex. Yellow = flammable, Blue = acid/corrosives), there is no official color-coding or color requirement for a storage cabinet. All Securall cabinets are available in any of the following standard colors: Yellow, Red, Blue, White, Beige, Gray, Pesticide Green, and Medical Green. Custom colors are available; contact your customer service representative.

WHERE DO I GO TO GET A PRICE FOR A CABINET?

For Pricing, please refer to a Securall distributor in your area. If you are not familiar with your local Securall Distributor, you can visit the Distributor Referral page on our website, or contact our customer Service Department for a referral in your area at custserv@Securallproducts.com, or 888-326-7890.

If you are a dealer looking to be set up as a online Securall Distributor, click here.

WHAT PAYMENT OPTIONS DOES Securall OFFER?

We extend options for credit with Net 30 Payment Terms, Cash, Money Order, Credit Card or Full Wire Transfer. For applicable payment terms, please contact our accounts receivable department: sales@Securallproducts.com , or fill out and submit a complete Credit Application and a Sales Representative will be in contact with you in the next 48 hours. Additional fees may also apply.

HOW SOON ARE THE CABINETS AVAILABLE TO SHIP AFTER I PLACE MY ORDER? All standard models are in stock and available to ship within 48 hours of order being placed. For large volume orders, please contact a Customer Service Representative for a lead-time. For custom units, please allow 4-6 weeks unless otherwise specified on the quote. This additional time allows for drawing approvals as well as design communication and implementation.

HOW CAN I OBTAIN A FREIGHT QUOTE AND WHAT INFORMATION DO I NEED? You can obtain a freight quote from any commercial freight carrier. If you have preferred carrier, please communicate that to your customer service representative at time of quote request. You will need the FOB Point (always 46350) and the ship-to zip code, the total weight, the number of pieces shipping, and the shipping dimensions. For standard cabinets, simply add 6” to the Height, and 4” to both the Width and Depth for palletizing. The shipping weight already includes the weight of the pallet. If you would like our logistics department to provide a carrier, simply contact your Customer Service Representative.

WHAT IS THE FREIGHT CLASS OF A SAFETY CABINET? All of our Dealer Price Listed Cabinet models ship freight Class 100. For a complete listing of item freight classes, click here.

HOW ARE THE CABINETS PACKAGED FOR SHIPPING?

Each cabinet is placed on a wooden pallet. Special waxed paper is placed in between the doors and the button latch to avoid paint wear during transport. The entire cabinet is bagged in thick heavy duty plastic. The corners of the sides and top of the cabinets are then covered in thick durable 48 ECT cardboard to prevent impact chipping, and the entire unit is wrapped in transparent cellophane from top to pallet and banded, allowing for inspection upon receipt of cabinet. Instruction stickers are then placed within the outer wrapping.