- Cabinets

- Safety Storage Cabinets

- Flammable Storage

- Hand Sanitizer Storage

- Stainless Steel Storage

- Drum Storage

- Paint & Ink Storage

- Laboratory Storage

- Acid & Corrosive Storage

- Hazardous Waste Storage

- Wall Mountable Storage

- Pesticide Storage

- Weatherproof Storage

- Dual Access Storage

- Tooling Storage

- Cylinder Storage

- Medical Gas Cylinder Storage

- LP Cylinder Storage

- Single Wall Storage

- Industrial Storage

- Stainless Steel Storage

- Spill Containment Storage

- Custom Storage

- Custom Cabinets

- Custom Cabinet - Form

- Miscellaneous

- Drum Spill Stations

- Parts & Accessories

- Replacement Parts

- Features & Compliance

- Standard Features

- Code & Compliance

- OSHA Training

- Buildings

- Storage Buildings

- Hazmat Storage Buildings

- Chemical Storage Buildings

- Custom Buildings

- Custom Building - Form

- Tornado Shelters

- Tornado Safe Rooms & Shelters

- Bid Specifications

- Hazmat Storage

- Chemical Storage

- Frequently Asked Questions

- Steel Doors

- New Arrivals

- Distributors

- Contact Us

- Safety Storage Cabinets

- Cylinder Storage

- Single Wall Storage Cabinets

- Custom Storage Cabinets

- Drum Spill Stations

- Mobile Work Benches

- Safety Storage Buildings

- Tornado Shelters

- Distributors

- Code & Compliance

- Catalog

- FAQ

- Contact Us

- Home

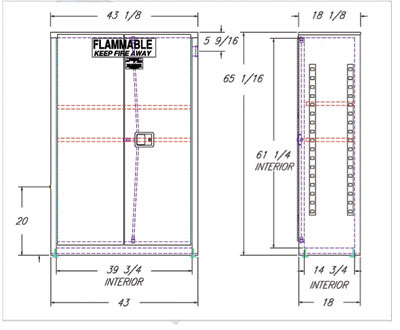

Flammable Storage

Models range from 4 to 90 gallon capacity. They are designed to meet safety requirements whenever a job involves the handling of flammable or combustible liquids. Smaller cabinets are convenient where space is limited.

Keep Flammable Liquids close to the work area in a safe and organized way while limiting employee exposure with Securall Safety Storage Cabinets. Cabinets are designed to meet safety requirements for the storage of Flammable Liquids. Choose from a large selection of models from 4 to 90 gallon storage capacity. Smaller compact cabinets are convenient where space is limited. All cabinets comply with current OSHA regulations and are designed in accordance with the standards of NFPA Code 30. Most models are FM approved.

Buy Securall Flammable Storage Cabinets at SecurallDirect.com (https://www.Securalldirect.com)

| |||||||||

| OSHA 1910 106.8. Flammable liquid means any liquid having a flash point below 100F (37.8C) or higher, the total of which make up 99 percent or more of the total volume of the mixture. Flammable liquids shall be known as Class I liquids. Class I liquids are divided into three classes as follows: Class IA shall include liquids having flash points below 73F (22.8C) and having a boiling point below 100F o(37.8C). Class IB shall include liquids having flash points below 73F (22.8C) and having a boiling point at or above 100F o(37.8C). Class IC shall include liquids having flash points at or above 73F (22.8C) and below 100F (37.8C). NFPA FLAMMABLE & COMBUSTIBLE CLASSES NFPA FLAMMABLE & COMBUSTIBLE CLASSES FLAMMABLES

Flash Point

Boiling Point

Class IA

<73°F (22.8°C)

<100°F (37.8°C)

Class IB

<73°F (22.8°C)

<100°F (37.8°C)

Class IC

<73°F (22.8°C) and <100°F (37°C)

- COMBUSTABLES

Flash Point

Boiling Point

Class IIA

<100°F (37.8°C) and <140°F (60°C)

-

Class IIIB

<140°F (60°C) and <200°F (93°C)

-

Class IIIC

<200°F (93°C)

-

It should be mentioned that flash point was selected as the basis for classification of flammable and combustible liquids because it is directly related to a liquid's ability to generate vapor, i.e., its volatility. Since it is the vapor of the liquid, not the liquid itself, that burns, vapor generation becomes the primary factor in determining the fire hazard. The expression "low flash - high hazard" applies. Liquids having flash points below ambient storage temperatures generally display a rapid rate of flame spread over the surface of the liquid, since it is not necessary for the heat of the fire to expend its energy in heating the liquid to generate more vapor.

| |||||||||